Take bed motion into account when printing narrow parts

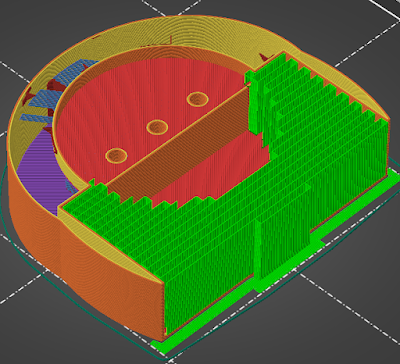

This is a bit embarrassing but I printed a chainsaw cosplay blade the other day and it went great. Then I re-sliced and reprinted. The 2nd print set failed when one of the pieces lost adhesion. It fell over . Part of the reason that happened is because I laid out the pieces aligned such that the narrow axis of the part was in the same direction as the bed movement. I then re-sliced oriented so that the parts lined up in the direction of motion and it printed without problems. Rafts and supports are great but sometimes you can help yourself by picking the right part/axis alignment. Video Short Revision History Created 2024/10