Two PCIe slots looked the same but gave different benchmark results - PCIe-2 vs PCIe-3

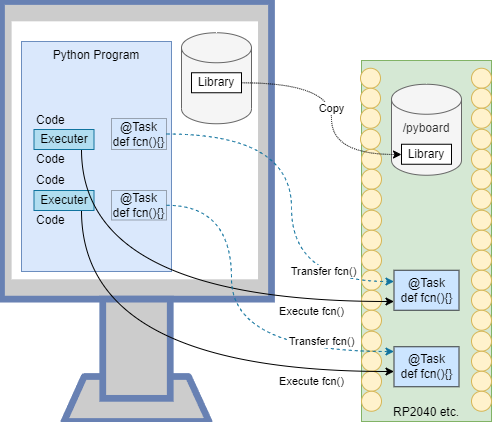

I benchmarked a new-old Intel P3700 PCIe disk drive I got off eBay in my HP Z820 and the P3700 seemed to underperform. I didn't get the performance I expected in a benchmark. I put the P37000 in the wrong PCIe slot. The HP Z820 machine has a bunch of PCIe-3, apparently one PCIe-2, and one classic PCI slot. All the connectors looked the same in the dark but one is not like the others. The P3700 was in the wrong slot. PCIe 3.0 supports a max speed of 8.0 GT/s while PCIe 2.0 supports a max speed of 5.0 GT/s. I have no idea if there was any real-world difference. PCIe 2.0 vs PCIe 3.0 These are two representative samples with an Intel P3700 in the v2 vs v3 slot. I ran both CrystalDiskMark tests with the Default setting not the more stressful NVMe configuration. There is a pretty significant boost in sequential performance moving from PCIe-2 to PCIe-3. The rest of the settings appear to be maxed out because the Default configuration doesn't generate enough load for an SSD o